EN

When it comes to modern architecture, facade design, and construction materials, aluminium solid panels and aluminium composite panels (ACP) are two of the most commonly used exterior cladding options. Both offer durability, aesthetics, and weather resistance—but they are not the same.

So, what exactly sets them apart?

Let's dive into a detailed comparison to help you choose the right one for your project.

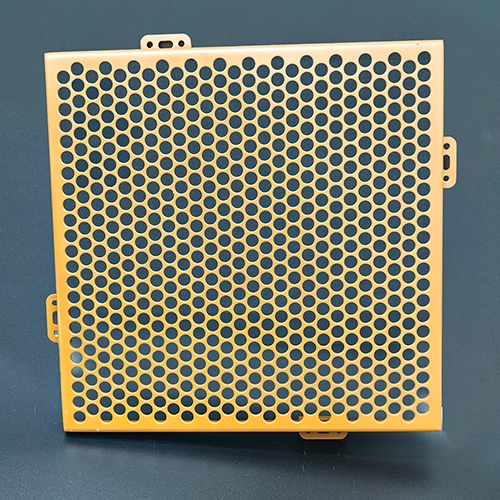

An aluminium solid panel —also known as solid aluminium sheet cladding—is made from a single, thick aluminium plate, usually ranging from 2mm to 5mm in thickness. It's fabricated from high-grade aluminum alloy (typically 3003 or 5005 series), and it's non-composite, meaning it doesn't contain any other materials.

The surface of the panel is typically powder-coated or PVDF-coated to provide:

UV resistance

Corrosion resistance

Custom color options

These panels are known for their strength, fire resistance, and durability.

An aluminium composite panel is a multi-layered sandwich panel, composed of:

Two thin aluminium skins (usually 0.3mm to 0.5mm thick)

A core layer (either polyethylene (PE) or fire-retardant mineral core)

A decorative or protective coating (PE or PVDF)

ACP was designed to offer an economical, lightweight, and decorative solution for cladding and signage, especially for high-rise buildings.

Let's look at how these two materials compare in different aspects:

Aluminium Solid Panel: Single, solid piece of aluminium.

ACP: Three-layered (aluminium + plastic/mineral core + aluminium).

Solid Panel: Heavier due to solid aluminum content.

ACP: Lighter, thanks to the plastic or mineral core.

Solid Panel: Stronger and more impact-resistant; can withstand heavy wind loads.

ACP: Adequate rigidity for many uses but may dent more easily under impact.

Solid Panel: Non-combustible and naturally fire-resistant.

ACP: Fire safety depends on the core—PE core is flammable, but FR (fire-retardant) cores are safer and meet international fire codes.

Both panels can be coated with PVDF or powder finishes, offering:

A wide range of colors

Metallic, woodgrain, and marble textures

Glossy or matte finishes

However, ACP tends to offer more graphic design flexibility, especially for signage and branding.

Solid Panel: More expensive due to the amount of aluminium used.

ACP: More affordable, especially for large surface areas.

Solid Panel: Heavier and requires stronger structural support and mounting systems.

ACP: Easier to install due to its lightweight nature; uses cassette systems or aluminum frames.

Solid Panel: Longer lifespan, more robust in extreme environments.

ACP: Good durability, especially with proper installation and quality coating.

Solid Panel: Can be curved or bent, but it requires specialized equipment.

ACP: Easily routed, folded, or curved using basic fabrication tools.

Solid Panel: 100% recyclable and easier to reclaim.

ACP: More complex to recycle due to mixed materials, although newer technologies are improving this.

| Feature | Aluminium Solid Panel | Aluminium Composite Panel (ACP) |

Structure | Single aluminium sheet | Sandwich: aluminium + core |

Weight | Heavier | Lightweight |

Fire Safety | Excellent | Depends on core type |

Cost | Higher | More affordable |

Durability | Very high | High |

Installation | Requires stronger support | Easy to install |

Design Flexibility | Moderate | Very high |

Recyclability | Easy | Complex (but improving) |

Government or landmark buildings

Airports and transportation hubs

High-rise building facades

Curtain walls requiring extra strength

Fire-prone or high-wind zones

Commercial and residential building facades

Signage and advertisement boards

Interior partitions and ceilings

Canopies and soffits

Retail shops and showrooms

The choice depends on project requirements.

Choose aluminium solid panels if you need:

High structural strength

Superior fire performance

Long-term durability

A solid, premium appearance

Choose ACP if you need:

Lightweight panels for easy installation

Affordable cladding solution

Creative design flexibility

Non-structural facade coverage

Both aluminium solid panels and aluminium composite panels are excellent materials—but for different reasons. The solid panel offers robust strength and unmatched fire resistance, ideal for high-stakes or high-traffic projects. Meanwhile, ACP delivers cost efficiency and design versatility, making it ideal for commercial facades and signage.

Understanding the technical differences and ideal applications will help you choose the right material for your architectural vision or construction needs.