EN

If you've ever worked with metal materials for construction, signage, or cladding, you've probably come across both aluminum composite panels (ACP) and aluminum sheets. At first glance, they might seem similar—they're both flat metal materials made with aluminum. But in reality, they are quite different in structure, performance, application, and cost.

So, what really sets them apart? Let's break it down step by step.

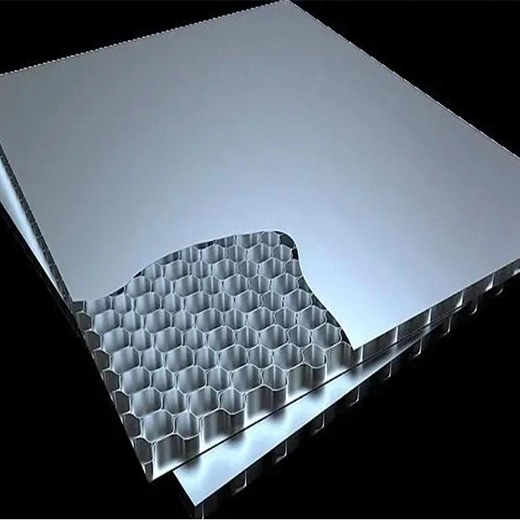

An aluminum composite panel is a sandwich structure. It typically consists of three layers:

A core made of polyethylene (PE) or a fire-retardant mineral-filled core.

Two thin aluminum sheets bonded to either side of the core.

A coating or laminated finish (such as PVDF or PE coating) for durability and aesthetics.

These panels are engineered to be lightweight, strong, and decorative, which makes them very popular in modern architecture and signage.

An aluminum sheet, on the other hand, is a solid piece of aluminum. It's made by rolling aluminum ingots into flat sheets of varying thicknesses. Depending on the alloy and temper, it can be soft or strong, corrosion-resistant, and highly conductive.

Aluminum sheets are versatile and can be cut, bent, or welded for various industrial and construction applications.

Let's compare them side-by-side for better clarity.

ACP: Multi-layered (aluminum + plastic core + coating)

Aluminum Sheet: Single, solid aluminum layer

ACP: Lighter due to its plastic core

Aluminum Sheet: Heavier and denser since it's solid metal

ACP: Good stiffness and strength-to-weight ratio

Aluminum Sheet: Stronger but less rigid unless thick

ACP: Can be bent with proper equipment but not suitable for welding

Aluminum Sheet: Can be bent, rolled, and welded easily

ACP: Comes in a variety of colors, finishes (matte, gloss, metallic), and textures

Aluminum Sheet: Usually comes in a mill finish or brushed look, and must be painted or anodized for color

ACP: Weather-resistant and corrosion-resistant due to coating

Aluminum Sheet: Highly durable, especially when anodized or coated

ACP: Can be a concern if made with non-fire-retardant core (check for FR grade)

Aluminum Sheet: Non-combustible and better for high-temperature environments

ACP: Generally more cost-effective for large coverage due to its lightweight structure

Aluminum Sheet: More expensive per square meter, especially in thicker gauges

ACP: Easy to install using a clip or frame system

Aluminum Sheet: Needs welding, riveting, or mechanical fastening

ACP: Wall cladding, facades, signboards, false ceilings, interior design

Aluminum Sheet: Roofing, industrial machinery, transportation, cookware, marine applications

Choose aluminum composite panels if you need:

Lightweight panels for cladding or facades

Attractive finishes and modern design

Budget-friendly large surface coverage

UV- and corrosion-resistant materials

Quick and easy installation

Go for aluminum sheets if your project requires:

High structural strength or load-bearing performance

Welding or fabrication into complex shapes

Heat-resistant material

Durability in industrial environments

Marine or aerospace-grade quality

Both materials are recyclable, but with a difference:

Aluminum sheets are easier to recycle as they are pure metal.

ACPs are more difficult to recycle due to the plastic core, though modern technologies have improved this process.

It depends on your needs. ACP is great for decorative and lightweight construction. Aluminum sheet is better for heavy-duty applications.

Think of it like this:

ACP is like plywood—layered, light, versatile.

Aluminum sheet is like solid wood—strong, dense, reliable.

Both aluminum composite panels and aluminum sheets are valuable materials in construction, signage, and manufacturing. Understanding the differences in structure, weight, cost, and performance helps you choose the right one for your specific application.