EN

When it comes to modern building materials, PUF panels and aluminum honeycomb panels are two leading options that serve very different purposes. If your project focuses on thermal insulation and affordability, PUF panels might fit the bill. But if you're targeting superior strength, durability, and high-end architectural performance, the aluminum honeycomb panel stands out as the better long-term solution.

Let's break down their performance in key technical areas.

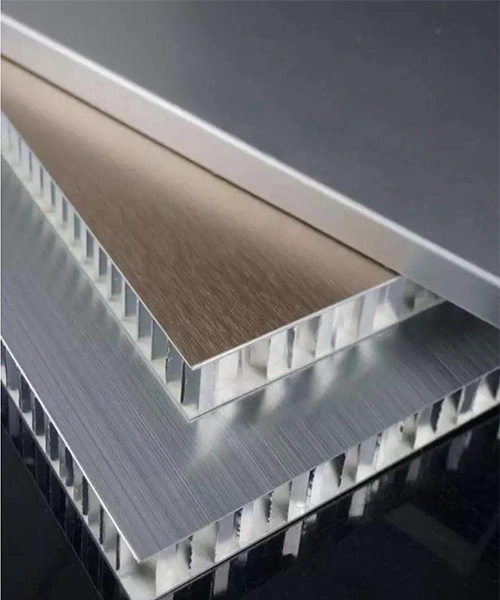

The aluminum honeycomb panel is designed for high strength-to-weight performance. Its unique honeycomb core acts like the web of an I-beam — lightweight yet incredibly strong. This allows for larger panel spans, reduced substructure, and better flatness compared to most foam-core panels.

PUF panels, by contrast, rely on a polyurethane foam core. While they provide decent rigidity for wall or roof applications, they are not engineered for structural loads or high façade performance.

Verdict: For façade cladding, curtain walls, and high-load architectural applications, aluminum honeycomb panels for sale offer unmatched stiffness and stability.

Here, PUF panels take the lead. Polyurethane foam is one of the best insulating materials in construction, providing low thermal conductivity and excellent energy efficiency. They are widely used in cold rooms, warehouses, and temperature-controlled environments.

Aluminum honeycomb panels, however, are designed for structural integrity rather than insulation. Unless the honeycomb cavities are filled with foam, their thermal resistance is lower.

Verdict: For energy-saving and temperature-sensitive projects, PUF panels deliver better insulation.

Fire performance is a major consideration in modern architecture.

PUF panels can be made fire-retardant but still rely on organic foam, which may release fumes under high heat if not treated properly.

Aluminum honeycomb panels, with their all-metal composition, are inherently non-combustible and can meet stringent façade fire ratings like Class A2 or higher.

Verdict: For high-rise or fire-critical buildings, aluminum honeycomb panels are the safer and more compliant choice.

Aluminum honeycomb panels excel in durability. Their corrosion-resistant aluminum skins and honeycomb core prevent warping, delamination, and deformation — even under extreme environmental exposure. PVDF or anodized coatings further extend their service life to 20 + years with minimal maintenance.

PUF panels perform well in moderate conditions but can deteriorate under prolonged UV or moisture exposure if not properly protected.

Verdict: For long-term façade stability and minimal maintenance, aluminum honeycomb panels outperform foam-based alternatives.

PUF panels are more affordable upfront and easier to install thanks to their simple joint systems. This makes them ideal for industrial sheds, warehouses, or prefabricated structures.

Aluminum honeycomb panels have higher initial costs due to precision bonding and finishing processes. However, their lightweight structure can reduce overall framework costs and provide excellent lifecycle value through reduced maintenance and longer lifespan.

Verdict:

Short-term projects or budget-sensitive builds → PUF panel.

Premium façade systems and long-term projects → aluminum honeycomb panel.

PUF panels are function-driven with limited color and texture choices.

Aluminum honeycomb panels, however, allow for wide customization — PVDF, powder-coated, or anodized finishes in any RAL color, metallic sheen, or even wood/stone textures. They can also be curved, bent, or perforated for creative façade designs.

Verdict: For architectural freedom and design aesthetics, aluminum honeycomb panels are far more versatile.

Aluminum honeycomb panels are made from fully recyclable aluminum, making them an eco-friendly option aligned with green-building standards like LEED.

PUF panels, though energy-efficient in use, involve chemical processes that are less sustainable and harder to recycle.

Verdict: Aluminum honeycomb panels have the upper hand in sustainability and circular-economy value.

| Feature | PUF Panel | Aluminum Honeycomb Panel |

Core Material | Polyurethane foam | Aluminum honeycomb structure |

Thermal Insulation | Excellent | Moderate |

Structural Strength | Medium | Very High |

Fire Resistance | Moderate (treated) | Excellent (non-combustible) |

Durability | Good | Superior |

Maintenance | Medium | Low |

Design Flexibility | Limited | Very High |

Sustainability | Moderate | Excellent |

Initial Cost | Low | Higher |

Lifespan | 10–15 years | 20–30 years + |

Are aluminum honeycomb panels stronger than PUF panels?

Yes. Aluminum honeycomb panels have much higher stiffness and load-bearing strength due to their honeycomb-core structure. They maintain excellent flatness and structural integrity even under high wind loads.

Which is better for exterior façades?

For exterior façades, aluminum honeycomb panels are recommended because they combine high strength, weather resistance, and fire safety with premium finishes.

Do PUF panels have better insulation?

Absolutely. PUF panels are designed primarily for insulation efficiency, offering better thermal performance in walls, roofs, and cold storage systems.

Which panel lasts longer?

Aluminum honeycomb panels can last over 25 years with proper coating and installation, while PUF panels typically last 10–15 years depending on exposure and maintenance.

Are aluminum honeycomb panels environmentally friendly?

Yes. They are 100% recyclable and have a lower lifecycle carbon footprint compared to foam-core panels, especially in long-service applications.

Both PUF panels and aluminum honeycomb panels play important roles in modern construction — but they serve very different needs.

Choose PUF panels when thermal insulation and cost efficiency are your priorities.

Choose aluminum honeycomb panels when you need lightweight strength, superior fire safety, and architectural durability.

For premium façade and interior cladding systems that combine aesthetics, performance, and sustainability, aluminum honeycomb panels remain the benchmark for high-end building design.